Introduction

When it comes to metal surfaces, achieving a polished finish can be a challenging task. It’s not just a matter of using any generic polishing compound and tool. Different types of metals require specific techniques and tools for polishing, and some surfaces can be especially tricky to work with. However, polishing metal is essential to preserve its appearance, prevent tarnishing, and increase its durability. In this complete guide, we will provide you with tips and step-by-step instructions to polish even the trickiest metal surfaces flawlessly.

The Importance of Polishing Metal

Polishing metal surfaces not only enhances the appearance of the object, but it also helps to protect it from rust and corrosion. It’s crucial to polish metal regularly, especially if it’s exposed to the elements or humidity. Polishing can help to extend the lifespan of metals as well as maintain their value. A clean and polished metal surface can vastly improve the aesthetic value of household items or jewelry, making them a standout feature.

However, it’s essential to ensure that the right polishing technique is used for specific metal types. Incorrect polishing techniques can lead to damage, such as scratches or discoloration, as well as ruin the artifact’s value. Understanding the metal surface and required techniques is essential for obtaining the desired finishing result.

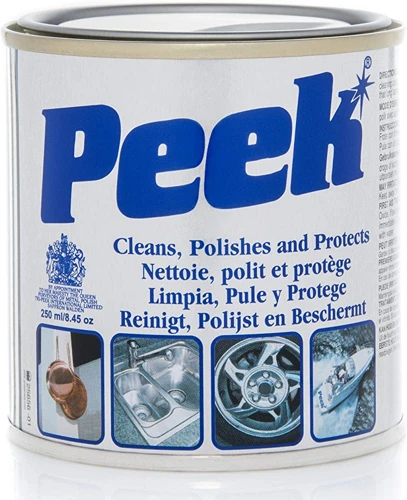

It’s important to choose the right materials for polishing. Using inappropriate polishing compounds or abrasive tools can likewise cause damage to the material. A polish’s abrasiveness should be carefully considered to avoid unintended damage to the metal surface. On the other hand, using a multi-purpose polish that includes a protective layer would benefit the metal surface even further.

Polishing metals may seem an arduous task, but it is a necessary and rewarding one. Once you have mastered the correct technique and materials for your metal surface, regular polishing helps to maintain the object’s shine, color, and value.

Types of Metal Surfaces

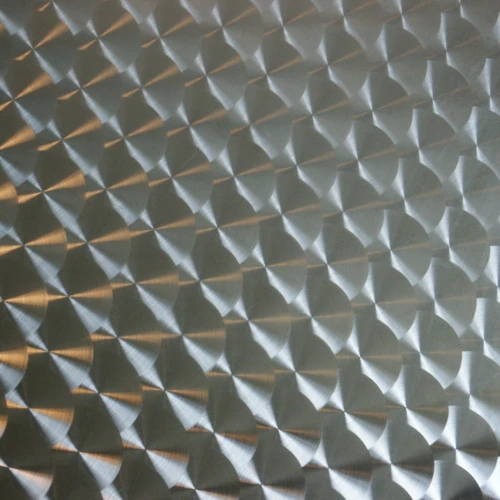

When it comes to polishing metal surfaces, it’s important to understand the various types of metals and their unique properties. Different metals may require different techniques and polishing compounds to achieve a flawless finish. From stainless steel to copper and brass, each metal presents its own set of challenges. Knowing how to properly identify and prepare these tricky surfaces for polish can make all the difference. In this section, we’ll discuss some of the common metal types and offer tips for achieving a polished look. For more tips on metal polishing, check out our article on choosing the right metal polish.

Identifying and Preparing Tricky Surfaces for Polish

Preparing tricky metal surfaces for polishing requires careful identification and attention to detail. Some metal types may be difficult to polish due to their unique properties, such as softness or malleability. To prepare tricky surfaces for the polishing process, follow these steps:

- Identify the type of metal: Before polishing any metal surface, it is essential to know the type of metal you are working with. Different metals have different properties, which can affect the polishing process, so be sure to identify the metal before proceeding further.

- Assess the condition of the metal: Take a close look at the metal surface to assess any damage or imperfections. If there are any deep scratches or dents, these will need to be addressed before polishing.

- Clean the surface: A clean metal surface is necessary for successful polishing, so make sure to remove any dirt, grime or contaminants before starting the polishing process.

- Protect any sensitive areas: If polishing metal jewelry or antiques, be sure to mask off any sensitive areas to avoid damaging them during the polishing process.

- Use a suitable polishing compound: Choosing the right polishing compound for the specific metal type is essential. A multi-purpose metal polish like XYZ All-in-One Metal Polish may be suitable for some metals, while more specific polishing compounds may be required for others.

By taking the extra time to correctly identify and prepare tricky metal surfaces, it is possible to achieve a high-quality polish without causing any damage to the metal. For more information on metal polishing, check out our DIY Metal Polishing Guide. Additionally, be sure to avoid any metal polish ingredients that can harm the surface in this article.

Polishing Tips for Common Metal Types

Polishing metal surfaces may seem like a simple task, but it can become challenging when dealing with certain types of metals. To achieve the best results, it’s crucial to consider the metal type and adjust your polishing technique accordingly. Here are some polishing tips for common metal types:

- Aluminum: Aluminum is a soft metal that can easily scratch, so it’s important to use a gentle polishing compound and avoid abrasive pads or cloths. Start by cleaning the surface before applying the polishing compound. Once the surface is polished, use a clean cloth to buff the surface to a shine.

- Brass: Brass is prone to tarnishing, so it’s important to clean it before polishing. Use a brass cleaner or a mixture of vinegar and salt to remove the tarnish. After cleaning, polish the brass using a soft cloth and mild polishing compound. Avoid using abrasive compounds on brass, as they can scratch or remove the finish.

- Copper: Like brass, copper can also tarnish. To restore copper surfaces, use a mixture of baking soda and lemon juice or vinegar to remove the tarnish. After the surface is clean, use a soft cloth and a mild polishing compound to bring back the shine.

- Chrome: Chrome is a hard, durable metal that can withstand abrasive polishing compounds. However, avoid using steel wool or abrasive pads that can scratch the surface. Start by cleaning the surface before applying the polishing compound. Use a soft cloth to buff the surface to a high shine.

- Stainless Steel: Stainless steel is a popular material for kitchen appliances and fixtures. It’s important to use a non-abrasive polishing compound and avoid scouring pads that can scratch the surface. Cleaning the surface beforehand is crucial to remove any stains or grime that may have accumulated. Once clean, use a soft cloth and polish in the direction of the grain to prevent scratching.

Remember, that different types of metals require different polishing techniques. With the right approach, even the trickiest metal surfaces can become shiny and new again.

Tools and Materials

When it comes to polishing tricky metal surfaces, having the right tools and materials is crucial for achieving a flawless finish. It’s not just about choosing the best polishing compound – you also need to have the appropriate equipment to apply it effectively. In this section, we will explore the various tools and materials you’ll need for successful metal polishing. From buffing wheels to protective gear, we’ll cover everything you need to know to confidently tackle any metal polishing project. Before we dive in, make sure you have read our previous sections on identifying surfaces for polish and cleaning vs. polishing to understand the importance of proper preparation.

What You Need for Successful Metal Polishing

To achieve a successful metal polishing, you need to have the right tools and materials. These items can determine the quality of your final result. Below is a table of essential tools and materials for metal polishing:

| Tools | Materials |

| Buffing wheel | Polishing compound |

| Polishing cloth | Protective gloves |

| Microfiber towel | Safety goggles |

| Rotary tool | Water |

| Steel wool | Masking tape |

The buffing wheel is a crucial tool for metal polishing as it helps smoothen the surface of the metal. The polishing compound is also essential as it removes any dirt and oxidation from the metal surface.

Using a polishing cloth or a microfiber towel can help polish hard-to-reach areas, while protective gloves and safety goggles can protect you from any potential harm when using the tools and materials.

A rotary tool is beneficial when polishing intricate metal pieces, and steel wool can be used to get rid of stubborn marks like rust.

Finally, masking tape may come in handy to protect parts that you don’t want to polish.

Make sure to have these tools and materials ready before attempting any metal polishing project to ensure successful results. If you want to know more about the frequency of metal polishing, you can check out our article on meta-polishing frequency.

Choosing the Best Tools for Tricky Metal Surfaces

When it comes to choosing the best tools for tricky metal surfaces, there are several important factors to consider. Here are some tips to help you choose the right tools to achieve the best results:

1. Evaluate the Surface: Before choosing any tools, examine the metal surface carefully. Determine its texture, hardness, and condition. This will help you choose the right abrasive and polishing tools.

2. Choose the Right Abrasive: Choosing the correct abrasive is crucial for a successful polish. The most common abrasives for tricky metal surfaces are sandpaper, emery cloth, and diamond abrasive pads. Diamond is the hardest and most effective abrasive, but it’s also the most expensive. For softer metals, such as copper or brass, use a less aggressive abrasive.

3. Select the Right Polishing Compound: The choice of polishing compound depends on the metal’s texture, condition, and type. Choose a compound that works well with the abrasive you selected earlier. Some compounds work best for rough surfaces, while others are better for smoother surfaces.

4. Consider Using a Polishing Wheel: Polishing wheels can make the process faster and easier for tough metal surfaces such as steel or iron. There are two types of polishing wheels: cloth and sisal. Cloth wheels are ideal for final buffing, while sisal wheels are more aggressive and ideal for initial polishing.

5. Don’t Forget Safety: Safety should always be a top priority when working with metal. Wear goggles or glasses to protect your eyes from flying debris. Also, wear gloves to protect your hands from sharp edges and heat produced during polishing.

By following these tips and choosing the right tools, you can achieve a perfectly polished metal surface that shines like new. For more information on polishing metal, check out our article on the difference between cleaning and polishing (source).

Step-by-step Guide for Polishing Tricky Metal Surfaces

Once you’ve identified and prepared the tricky metal surfaces for polish, it’s time to start the actual polishing process. This step-by-step guide will help you make your metal surfaces shine like new. Follow these easy instructions carefully, and you’ll be able to restore even the most difficult metals to their former glory. From cleaning and preparing the surface to polishing and buffing, we’ll show you how to complete the process safely and effectively. By the end of this guide, you’ll see that polishing metal doesn’t have to be a daunting task. It’s a rewarding activity that will leave you with shiny and attractively-looking metal surfaces. So let’s begin! Don’t forget, If you want to learn more about where to start with restoring tarnished metal, follow this link here. Or, for tips on polishing metal jewelry, click here here. And for help polishing antique metals safely, proceed to this link here.

Clean and Prepare the Metal Surface

Before beginning the polishing process, it is important to properly clean and prepare the metal surface. This step is crucial in order to achieve a smooth and shiny finish. Below are some steps you can take to ensure your metal surface is ready for polishing.

| Step 1: | Remove any dirt or debris from the surface using a soft-bristled brush or a microfiber cloth. |

| Step 2: | Use a metal cleaner to remove any stubborn stains or marks on the surface. Be sure to follow the instructions on the cleaner carefully and use a product that is appropriate for the type of metal you are working with. |

| Step 3: | Rinse the surface thoroughly with clean water to remove any residue from the cleaner. |

| Step 4: | Dry the surface completely using a clean and dry microfiber cloth to ensure there are no water spots or streaks left behind. |

| Step 5: | Use a fine sandpaper or steel wool to remove any scratches or blemishes on the surface. Be sure to use gentle pressure and work in the direction of the grain to avoid further damage. |

| Step 6: | Wipe the surface with a clean, dry microfiber cloth to remove any debris or dust left from sanding. |

Taking the time to properly clean and prepare your metal surface before polishing can make a significant difference in the end result. Skipping this step can lead to a less than perfect finish and even cause further damage to the surface.

Apply Polishing Compound

After cleaning and preparing the metal surface, the next step is to apply polishing compound. The type of polishing compound you use will depend on the type of metal you’re polishing and the level of shine you want to achieve.

To help you choose the right polishing compound, refer to the table below:

| Metal Type | Polishing Compound |

|---|---|

| Chrome | Chrome polish |

| Stainless Steel | Stainless steel polish |

| Aluminum | Aluminum polish |

| Brass | Brass polish or vinegar and salt solution |

When applying the polishing compound, use a clean microfiber cloth or a polishing pad. Apply a small amount of the compound to the cloth or pad and gently rub it onto the metal surface using circular motions. Start with a small area and work in sections until the entire surface is covered.

It’s important to avoid using too much polishing compound, as this can lead to a buildup on the surface that can be difficult to remove.

After applying the polishing compound, let it sit for a few minutes to allow it to work its magic. Then, use a clean microfiber cloth to remove any excess polish and gently buff the surface.

By following these steps and using the right polishing compound, you can achieve a shiny, polished finish on even the trickiest metal surfaces.

Polish the Surface

After applying the polishing compound, it’s time to start polishing the surface. This is where the real work begins, but the end result is definitely worth it. Here are the steps for effectively polishing tricky metal surfaces:

| Step | Description |

|---|---|

| Step 1: | Begin polishing the metal surface with a consistent back-and-forth motion, applying pressure evenly. Be careful not to apply too much pressure as it can damage the surface. |

| Step 2: | Continue polishing until the surface begins to show signs of improvement. Keep in mind that this can take some time, so be patient and persistent. |

| Step 3: | Once the surface has improved, switch to a circular motion. This will help to remove any remaining scratches and evenly distribute the polishing compound. |

| Step 4: | If necessary, apply more polishing compound to the surface as you continue to polish. This will help to achieve the desired level of shine. |

| Step 5: | Continue polishing until you are satisfied with the level of shine on the metal surface. Take breaks as needed to avoid fatigue. |

Keep in mind that the key to effective polishing is taking your time and being consistent with your technique. Rushing the process or using inconsistent movements can lead to uneven results or even damage to the surface.

Buff the Surface

To complete the polishing process, the final step is to buff the surface to a high shine. Buffing involves using a soft cloth or a buffing wheel to remove any remaining polish and bring out the luster of the metal. Here are the steps for buffing a tricky metal surface:

- Clean the Surface: Before buffing, make sure the surface is free of any polishing compound or debris. Use a clean microfiber cloth to wipe down the surface and remove any lingering particles.

- Choose the Right Buffing Wheel: Depending on the shape and size of the surface, you may need to choose a specific type of buffing wheel. A loose-sewn or Canton flannel wheel is best for flat surfaces. A tight-sewn or sisal wheel is better for corners and crevices.

- Apply the Polishing Compound: Apply a small amount of polishing compound to the buffing wheel. Turn on the wheel and move the metal surface back and forth against the rotating wheel. Use a light touch, as too much pressure can damage the surface.

- Move in a Circular Motion: To achieve a high shine, move the metal surface in a circular motion against the buffing wheel. Keep the surface moving in a consistent pattern, and check frequently to make sure the metal isn’t getting too hot or starting to warp.

- Repeat the Process: Depending on the type of metal and the desired level of shine, you may need to repeat the buffing process multiple times. Apply additional polishing compound as needed, but be careful not to overuse it.

- Wipe Away Residue: Once you’ve achieved the desired level of shine, turn off the buffing wheel and wipe away any residue with a clean microfiber cloth.

By following these steps, you can effectively buff tricky metal surfaces to a high shine. Remember to take your time and be gentle with the surface to avoid causing any damage.

Common Mistakes to Avoid

When it comes to polishing tricky metal surfaces, mistakes can happen despite your best efforts. However, some mistakes can be avoided with proper awareness and precautions. In this section, we will discuss some common mistakes that you should be aware of and how to avoid them. By being mindful of these mistakes, you can achieve a flawless and long-lasting shine on your metal surfaces. So, let’s delve into these common mistakes to ensure a successful polishing process.

Skipping Steps

One of the most common mistakes people make when polishing tricky metal surfaces is skipping important steps in the process. While it may be tempting to cut corners or rush through the polishing process, doing so can ultimately lead to disappointing results.

Here are some steps that you should never skip when polishing metal surfaces:

- Cleaning the surface: Before you begin polishing, it’s essential to clean the metal surface thoroughly. Removing any dirt, grime, or other debris will allow the polishing compound to work more effectively and help prevent scratching or other damage.

- Prepping the surface: If you’re dealing with a particularly tricky metal surface, you may need to take some extra steps to prepare it properly for polishing. This might include removing any rust or oxidation, smoothing out rough spots, or using a special primer to help the polishing compound adhere more effectively.

- Using the right tools: When it comes to polishing metal surfaces, choosing the right tools is crucial. Depending on the type of metal you’re working with and the desired level of shine, you may need to use different abrasive pads, polishing compounds, or other materials. Using the wrong tools can lead to uneven or unsatisfactory results.

- Taking your time: Depending on the size and complexity of the metal surface you’re polishing, the process can take anywhere from a few minutes to several hours. Rushing through the process or cutting corners can lead to uneven results and may even damage the surface. Take your time and be patient, and you’ll be rewarded with a beautiful, shiny metal surface.

Remember: each step in the polishing process is important, and skipping any of them can ultimately lead to disappointing results. Take the time to properly clean and prepare the surface, choose the right tools, and be patient as you work your way through the polishing process. By doing so, you’ll be sure to get the best possible results and enjoy a beautiful, gleaming metal surface.

Overusing Polishing Compounds

When it comes to metal polishing, using the right amount of polishing compound is crucial. Overusing polishing compounds can result in several problems which can affect the quality of the finished product. Here are some of the issues that may arise from overusing polishing compounds:

- Waste of Material: Overusing polishing compounds means more product is used than necessary. This can lead to wastage, which is not only costly but also harmful to the environment.

- Difficulty in Removing Compound: Excessive polishing compound may leave a residue on the metal surface, which can be challenging to remove. This can result in additional work to clean the surface.

- Damage to Metal: Some polishing compounds are abrasive and can cause permanent damage to the metal surface if used excessively. This can result in scratches, pits, or other types of damage that cannot be repaired.

- Overheating of Metal: Overuse of polishing compound can result in excessive friction, which can heat up the metal surface. This can cause warping or other types of damage that are difficult to fix.

It’s essential to use polishing compounds sparingly and follow the manufacturer’s instructions for best results. It is recommended to start with a small amount of polishing compound and gradually increase it until the desired level of shine is achieved. Remember, less is often more when it comes to polishing compounds. By using the right amount of compound, you can achieve a high-quality finish without any negative consequences.

Using the Wrong Tools

Using the wrong tools for polishing metal surfaces can lead to unsatisfactory results and even damage to the metal itself. It is important to select the right tools for the particular metal surface you are working on. Some common mistakes to avoid when it comes to selecting polishing tools include:

- Using Abrasive Materials on Delicate Surfaces: Abrasive materials like steel wool or abrasive pads can scratch or damage delicate metal surfaces like chrome or aluminum. It is better to use softer materials like microfiber cloths or foam pads on such surfaces.

- Using Too Coarse or Too Fine Abrasive Materials: Using abrasive materials that are too coarse can leave deep scratches on the metal while using materials that are too fine may not be effective in removing scratches. It is important to select the right level of abrasiveness for the job at hand.

- Using Polishing Compounds that are not Suitable for the Metal: Different metals require different polishing compounds. Using a polishing compound that is not suitable for the specific metal surface you are polishing can lead to damage or discoloration.

- Using Cheap or Low-Quality Buffing Pads: Buffing pads that are cheap or of low quality may leave behind small fibers or pieces of pad that can stick to the metal surface and be difficult to remove.

It is important to do research and carefully select the right tools for the job to avoid making these common mistakes, and to ensure a successful and high-quality metal polishing job.

Not Protecting the Surface

Protecting the surface of the metal during the polishing process is important to ensure that the metal retains its shine and does not become damaged. Here are a few ways to protect the surface of your metal while polishing:

- Use masking tape: Cover any surrounding areas that do not need to be polished with masking tape to ensure the polishing compound does not come into contact with them.

- Avoid harsh chemicals: Certain chemicals can damage the surface of the metal. When cleaning the metal prior to polishing, use a mild cleaner and avoid harsh chemicals such as bleach or ammonia.

- Use a soft cloth: When buffing the metal, use a soft cloth or microfiber towel to avoid scratching the surface.

- Avoid excessive pressure: Do not apply excessive pressure while polishing the metal as this can cause the surface to become scratched or damaged.

- Apply a protective coating: Once the polishing process is complete, apply a protective coating to the surface to help prevent future damage or staining.

Keeping these tips in mind will help ensure that your metal surfaces shine without sustaining any damage during the polishing process.

Conclusion

As we come to the end of this comprehensive guide on polishing tricky metal surfaces, it’s time to reflect on the valuable tips and techniques we’ve covered. With the help of the right tools and materials, you can achieve a flawless shine on even the most difficult metal surfaces. However, it’s important to avoid common mistakes that can lead to subpar results or even damage to the metal itself. Keep these do’s and don’ts in mind as you embark on your next metal polishing project, and enjoy the satisfaction of a job well done.

Enjoy Your Shiny Metal Surfaces

After following the step-by-step guide and avoiding common mistakes, you should have a collection of shiny metal surfaces that will make your friends and family envious. To fully enjoy the fruits of your labor, here are some tips to keep your metal surfaces looking their best:

1. Regular cleaning: Keep your metal surfaces free of dirt and grime by regularly cleaning them with a soft cloth and mild soap and water. Avoid using harsh chemicals, as they can damage the metal and its finish.

2. Protective coating: Consider applying a protective coating, such as a wax or sealer, to prevent future tarnishing or corrosion. Follow the manufacturer’s instructions carefully and reapply as needed.

3. Gentle handling: When handling your newly polished metal surfaces, use caution and avoid touching them with dirty or greasy hands. Be mindful of any surfaces that may scratch or damage the metal, and take the necessary precautions to protect them.

4. Display with care: When displaying your metal surfaces, choose a location that is free from excessive heat, humidity, or direct sunlight. These conditions can cause the metal to tarnish or even warp over time.

5. Showcase your collection: Show off your collection of shiny metal surfaces in a way that highlights their unique beauty. Group similar pieces together or mix and match metals for an eclectic look.

By following these tips, you can enjoy your polished metal surfaces for years to come. So take a step back, admire your work, and bask in the glow of your shiny new treasures.

Frequently Asked Questions

What types of metal should be polished?

Most metal surfaces can benefit from polishing, including stainless steel, aluminum, brass, copper, and silver.

Why is polishing metal important?

Polishing metal not only restores its shine but also helps protect it from corrosion, rust, and other types of damage.

What are some tricky metal surfaces to polish?

Tricky metal surfaces include those with intricate designs, deep crevices, and uneven textures, such as patterned silverware, antique brass objects, and ornate jewelry.

What is the best way to prepare metal surfaces for polishing?

The best way to prepare metal surfaces for polishing is to thoroughly clean them with a degreaser and a soft cloth, and then dry them completely before starting the polishing process.

What materials do I need for metal polishing?

You will need a polishing compound, a soft cloth, gloves, safety glasses, and a buffing wheel or other tool for buffing the metal.

Can I use household items to polish metal?

Some household items, such as baking soda, vinegar, and lemon juice, can be used for polishing metal. However, it is best to use specialized metal polishing products for optimal results.

What is the best way to avoid scratches on metal surfaces while polishing?

The best way to avoid scratches is to use a soft cloth and be gentle while polishing. Also, avoid using abrasive materials and make sure to remove any dirt or dust from the surface before polishing.

How often should I polish my metal surfaces?

This depends on how often the metal is used and exposed to elements that can tarnish it. However, it is a good idea to polish metal surfaces every few months to keep them looking their best.

What should I do if I accidentally over-polish a metal surface?

If you accidentally over-polish a metal surface, you can try using a fine-grit sandpaper to buff out the scratches or ask a professional metal polisher for assistance.

Can polishing metal surfaces cause any health risks?

Yes, polishing metal surfaces can release fine dust particles that can be harmful if inhaled. It is important to wear gloves and safety glasses and to work in a well-ventilated area.