Have you ever wondered about the science behind the sparkling, gleaming surfaces that catch your eye? We all love a good shine, whether it’s on our cars, jewelry, or household items. But have you ever stopped to think about how polish actually works to create that shine? It turns out that the chemistry of polish is a complex topic with many factors to consider, including the chemicals involved and how they interact with surfaces. In this article, we’ll explore the science behind shine and dive into the nitty-gritty of the chemical properties of polish. We’ll also cover tips for choosing the right polish, polishing techniques, and maintaining your shine over time. So if you’re ready to get your shine on, read on!

The Chemistry of Polish

When we talk about achieving a beautiful shine on our surfaces, we often rely on the magic of polish. But what exactly is polish, and how does it work? The chemistry of polish is a complex topic that can seem daunting to the uninitiated. However, understanding the chemical properties of polish is key to achieving the perfect shine. In this section, we’ll delve into the components of polish and how they work together to create its shine-boosting powers. So, whether you’re looking to enhance the shine and resilience of your car’s paintwork or searching for eco-friendly and budget-friendly DIY polish recipes, this section will provide you with a solid foundation to understand the science behind it all.

What is Polish?

Polish is a substance that is commonly used to enhance the appearance of various surfaces. It is a mixture of different chemicals that work together to create a polished effect on surfaces. Polish is different from wax, which is a protective substance that is applied to surfaces to provide a layer of protection. Polish, on the other hand, is applied to surfaces to make them shiny.

The primary purpose of polish is to make surfaces look shiny and new. It is commonly used on various surfaces such as cars, furniture, floors, and even shoes. Polish contains various chemicals that are designed to help it adhere to surfaces and create a shine.

Here is a table outlining the different chemicals found in polish and their function:

| Chemical | Function |

|---|---|

| Solvent | Dissolves other chemicals and allows them to be spread evenly |

| Emulsifiers | Helps the polish to mix with water |

| Fillers | Fill in scratches and other imperfections on surfaces to create a smoother appearance |

| Abrasives | Removes a thin layer of the surface material to even out scratches and other imperfections |

| Surfactants | Helps the polish to spread evenly on the surface |

| Conditioners | Protects the surface from further damage and makes it easier to clean in the future |

These chemicals work together to create a smooth, shiny surface that is free of scratches and other imperfections. However, not all polishes are created equal. The type of polish you use will depend on the surface you are working with and the result you are trying to achieve.

If you want to learn more about the difference between polish and wax, check out this article. Alternatively, if you are interested in making your own eco-friendly polish, check out this article. Finally, if you are interested in learning about the benefits of using furniture polish, click here. Additionally, if you want to learn how to polish wooden surfaces like a pro, click here.

The Chemicals in Polish

Polishes are made up of several different chemicals, each with their own unique properties that contribute to the final shine. Here’s a breakdown of some common chemicals found in polishes and what they do:

| Chemical | Function |

|---|---|

| Abrasive | Removes surface imperfections by physically wearing them away. Examples include aluminum oxide, silica, and calcium carbonate. |

| Solvent | Dissolves dirt, oils, and other contaminants on the surface. Common solvents in polish include mineral spirits, ethanol, and acetone. |

| Binder | Helps the polish adhere to the surface being polished. These are often synthetic resins that harden when they dry, creating a protective layer over the surface. Examples include polyurethane, acrylics, and siloxanes. |

| Surfactant | Reduces surface tension and helps the polish spread more evenly across the surface, ensuring consistent coverage. Examples include sodium laureth sulfate and cocamidopropyl betaine. |

| Pigment | Provides color to the polish. Pigments can either be natural or synthetic, and they can add to or detract from the shine of the surface. Some common pigments found in polish are iron oxide and titanium dioxide. |

| Defoamer | Prevents the formation of bubbles or foam in the polish, which can interfere with the machining process or detract from the shine. Examples of defoamers used in polish include silicone oils and dimethyl polysiloxanes. |

| pH Adjuster | Modifies the pH of the polish to make it more effective at removing certain types of stains or contaminants. This can also help increase the gloss of the surface being polished by balancing the pH level. Examples of pH adjusters include citric acid and sodium hydroxide. |

These chemicals work together to create a final polish that is effective at removing imperfections, protecting the surface, and producing a high gloss shine. However, not all polishes are equal, and it’s important to choose a polish that is appropriate for the surface you are trying to polish.

How They Work Together

The combination and interaction of different chemicals in polish is crucial for achieving shine on surfaces. Let’s take a closer look at how they work together.

| Chemical | Function |

|---|---|

| Carnauba wax | Provides a protective barrier against water and other contaminants, while enhancing shine. |

| Micro-abrasives | Gently remove a thin layer of oxidized paint or plastic, allowing the glossy, unoxidized layer to show. |

| Solvents | Dissolve and help remove dirt, grime, and other substances that can dull a surface. |

| Silicone polymer | Acts as a water-repelling agent, improving the water beading effect on surfaces. |

| Surfactants | Lower the surface tension of water, making it easier to spread the polish evenly on a surface. |

Carnauba wax is a natural wax derived from the leaves of the carnauba palm tree. It has a high melting point, which means it can handle high temperatures and provides a long-lasting, protective barrier on the surface. Micro-abrasives are tiny particles that are used to polish surfaces. They gently remove a thin layer of oxidized paint or plastic, allowing the glossy, unoxidized layer to show through.

Solvents are used to dissolve and help remove dirt, grime, and other substances that can dull a surface. This allows for a clean, smooth surface that can be easily polished. Silicone polymer is an important ingredient in polish that acts as a water-repelling agent, improving the water beading effect on surfaces.

Finally, surfactants lower the surface tension of water, making it easier to spread the polish evenly on a surface. This helps the polish adhere to the surface and improve the overall shine. When these chemicals work together, they can provide a long-lasting, high-shine finish on a variety of surfaces.

The Science of Shine

As we gaze upon a shiny surface, we can’t help but wonder: what is the science behind the amazing shine that catches our eye? The answer lies in understanding how light interacts with surfaces and how polishing agents enhance this interaction. With every reflection and glimmer, the science of shine reveals itself. In this section, we will delve deeper into the chemical and physical principles behind the science of shine, so you can understand why that smooth, polished surface is so captivating.

How Light Interacts with Surfaces

When it comes to understanding the science behind shine, it’s important to first examine how light interacts with surfaces. Light is a form of electromagnetic radiation that travels in waves, and the way it interacts with a surface depends on the properties of that surface.

One important property of a surface is its texture. When light hits a textured surface, it is scattered in many different directions. This means that the surface doesn’t appear shiny, but instead appears dull and matte.

On the other hand, when light hits a smooth surface, it is reflected in a more uniform way. The surface appears shiny because the light waves are bouncing off the surface and being directed back at the viewer in a more organized fashion.

The way that light interacts with a surface also depends on the angle of incidence. This refers to the angle at which the light hits the surface. When the angle of incidence is perpendicular to the surface, the light is able to bounce back in a more direct way, resulting in a brighter and more intense shine.

However, when the angle of incidence is not perpendicular, the light is bounced back in a less direct way, resulting in a less intense shine.

Understanding how light interacts with surfaces is crucial for understanding the science behind shine. By choosing the right polishing technique and product, you can help to create a smooth surface that will better reflect light and provide a more impressive shine.

Why Polish Makes Surfaces Shiny

Polish makes surfaces shiny due to the way light interacts with the surface. When light hits a surface, it is either absorbed, reflected or scattered. The amount of light that is reflected back to our eyes determines how shiny something appears.

Reflection is the key to creating shine. Smooth surfaces reflect light more efficiently than rough or textured surfaces. When light hits a smooth surface, it bounces back at the same angle as it hit the surface. This creates a mirror-like effect that we perceive as shine.

Polish helps to create a smooth surface by filling in microscopic imperfections, bumps, and scratches. This is achieved through the use of fine abrasives and chemical cleaners. The process of polishing removes a microscopic layer of the surface, revealing a smooth layer underneath. This new smooth layer reflects light more efficiently, resulting in a shinier appearance.

Absorption and Scattering are other ways that light interacts with surfaces. When light is absorbed by a surface, it is not reflected back to our eyes. The surface appears dull and non-reflective. Scattering occurs when light is deflected in many different directions, creating a diffused or hazy appearance.

Polish makes surfaces shiny by creating a smooth surface that reflects light more efficiently. This process involves the use of abrasives and cleaners to remove imperfections and reveal a smooth layer underneath. The result is a mirror-like shine that we perceive as clean and attractive.

| Interaction with Light | Description | Appearance |

|---|---|---|

| Reflection | Light bounces back at the same angle as it hits a smooth surface | Shiny, mirror-like |

| Absorption | Light is absorbed by surface and is not reflected | Dull, non-reflective |

| Scattering | Light is deflected in many different directions | Diffused, hazy |

The Importance of a Smooth Surface

A smooth surface is crucial for achieving a high shine when polishing. Polishing is essentially the process of removing any imperfections or irregularities from a surface in order to create a smooth and reflective surface. Any bumps, scratches, or other surface imperfections can cause light to scatter in different directions, which reduces the overall shine of the surface.

When light hits a rough surface, it scatters and reflects in many different directions, resulting in a dull appearance. In contrast, when light hits a smooth surface, it reflects uniformly in one direction, creating a mirror-like reflection. This is why it is necessary to have a smooth surface when we want to create a shiny appearance.

During the process of polishing, abrasives are used to remove a thin layer of surface material to create an even surface. The level of abrasiveness varies depending on the type of surface being polished. For example, some surfaces such as glass require very fine abrasives, while others such as metals require coarser abrasives.

A smooth surface is also important for the longevity of the shine. A rough surface can trap dirt and grime, which can lead to the surface becoming dull and discolored over time. A smooth surface, on the other hand, is easier to clean and maintain, making it more likely that the surface will retain its shine for longer periods of time.

Ultimately, the importance of a smooth surface in polishing cannot be overstated. No matter how high-quality the polish used, if the surface is not smooth and free of imperfections, the shine will not be at its maximum potential. It is important to take the time to properly prepare the surface before polishing, and to regularly maintain it in order to keep it smooth and reflective.

| Importance of a Smooth Surface |

|---|

| A smooth surface creates a mirror-like reflection and provides a high shine. |

| When light hits a rough surface, it scatters in many directions, resulting in a dull appearance. |

| Abrasives are used to remove imperfections and create an even surface. |

| A smooth surface traps less dirt and grime, making it easier to clean and maintain. |

| The longevity of the shine is significantly increased when the surface is smooth and free of imperfections. |

Choosing the Right Polish

When it comes to choosing the right polish for a specific surface, the task can often seem daunting. With so many brands, chemical compositions, and surface types to consider, how do you know where to start? It’s important to make an informed decision to not only achieve optimal shine, but also to prevent damage to the surface being polished. Let’s take a closer look at the factors to consider when selecting a polish.

Surface Type

When choosing the right polish for your surfaces, the type of surface plays a significant role in determining which product is most effective. Different surfaces require different chemical compounds to achieve the best shine possible.

Here is a breakdown of common surface types and the types of polish that work most effectively:

| Surface Type | Types of Polish |

|---|---|

| Painted Surface | Polish specifically formulated for painted surfaces that contain wax or a polymer sealant. |

| Chrome or Metal | Metal polishes that contain a mixture of solvents and abrasives, allowing for a shinier and smoother appearance. |

| Glass | Glass polishes or cleaners that are formulated to remove scratches, water spots, and any other impurities that may appear on the surface. |

| Plastic or Vinyl | Polish that contains a mild abrasive to remove scratches and restore a clear, smooth appearance to the surface. |

| Leather or Upholstery | Leather conditioners that contain natural oils to nourish and protect the material, restoring its suppleness and shine. |

It is important to note that using the wrong polish on a surface can cause damage and potentially ruin the appearance of the surface. Always check the label of the polish to make sure it is safe to use on the surface you intend to clean and restore.

Chemical Composition

When it comes to choosing the right polish, the chemical composition is an important factor to consider. Different polishes contain different chemicals that are formulated for specific uses and surfaces.

Here are some key chemicals to look for in polish:

- Abrasive agents: These chemicals help to remove imperfections on the surface, such as scratches or swirl marks. Common abrasive agents include aluminum oxide, silicon carbide, and pumice. They are often found in heavy-duty polishes used for metal surfaces.

- Solvents: Solvents are used to dissolve dirt, oil, and grime on the surface. This makes it easier to remove them during the polishing process. Common solvents include mineral spirits, naphtha, and acetone. They are often found in polishes used for automotive and household surfaces.

- Oxidizers: Oxidizers are used to remove discoloration and stains on the surface. They work by breaking down the chemical bonds that make up the stain. Common oxidizers include hydrogen peroxide, sodium percarbonate, and chlorine bleach. They are often found in polishes used for countertops and tile surfaces.

- Protective agents: Protective agents are used to create a barrier on the surface that helps to prevent future damage. Common protective agents include waxes, silicones, and polymers. They are often found in polishes used for cars, boats, and furniture.

It’s important to choose a polish that contains the right combination of these chemicals for your particular surface. Using a polish with abrasive agents on a delicate surface, for example, could cause damage. Additionally, some chemicals may not be safe for use on certain surfaces, so always read the manufacturer’s instructions before using a polish.

Brand Comparisons

When it comes to choosing the right polish for your needs, one factor to consider is the brand. With so many brands on the market, it can be overwhelming to know which one to choose. To make your decision easier, we’ve compared some of the top brands based on their chemical composition, effectiveness, and ease of use.

| Brand A | Brand B | Brand C | |

|---|---|---|---|

| Chemical Composition | Contains high levels of silicone, which provides long-lasting protection | Uses a blend of natural oils and waxes for a more eco-friendly option | Formulated with micro-abrasives for deep cleaning and scratch removal |

| Effectiveness | Provides a high level of shine and protection, but can be difficult to remove from surfaces | Offers a more subtle shine, but is easy to apply and remove | Can effectively remove deep scratches and provide a long-lasting shine, but may require more effort to apply |

| Ease of Use | May require multiple applications and buffing to achieve desired results | Can be easily applied with a cloth or buffer, and is easily removed with a soft cloth | Requires a bit more effort to apply and remove, but provides a deep and long-lasting shine |

Keep in mind that different brands may work better for different types of surfaces and applications. It’s important to do your research and choose a polish that is best suited for your specific needs.

Polishing Techniques

When it comes to polishing, there are various techniques that people use to ensure that their surfaces are as shiny and smooth as possible. However, with so many options available, it can be challenging to determine the best approach for your specific needs. In this section, we’ll explore some popular polishing techniques, including manual techniques and machine buffing, and provide you with some tips and tricks to make sure that your surfaces shine like new.

Manual Techniques

One of the most popular ways to polish a surface is to use manual techniques. This method involves using your hands to apply and manipulate the polish. Here are some common manual techniques for polishing:

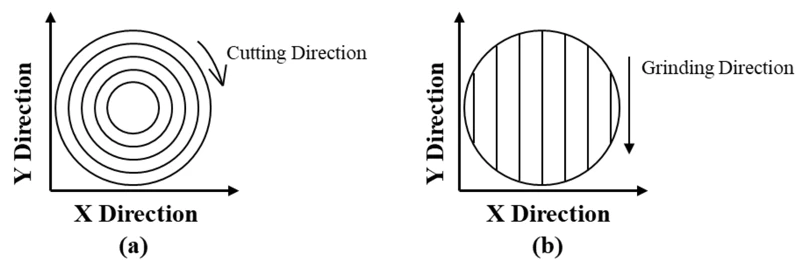

- Hand Application: This technique involves using a cloth, foam applicator pad, or your bare hands to apply the polish to the surface. Rub the polish in a circular or back-and-forth motion until it is evenly distributed.

- Finger Pressure: When using your hands to apply the polish, you can also apply different levels of finger pressure to create the desired shine. Light pressure will create a subtle sheen, while firm pressure will create a high gloss shine.

- Microfiber Cloth: A microfiber cloth is a great tool for buffing and removing polish from the surface. Use a clean microfiber cloth to gently buff the surface in a circular motion until the desired shine is achieved.

- Polishing Gloves: Polishing gloves are a recent addition to the market and are designed to make polishing easier and more efficient. They are made of microfiber and have a special grip that helps you apply more pressure for a better shine.

It’s important to note that manual techniques can be time-consuming and require a lot of effort. However, they are also the most affordable and accessible option for many people. When using manual techniques, it’s important to choose the right type of cloth, applicator pad, or polishing glove to avoid scratching the surface. It’s also a good idea to start with a small area to test the technique and ensure that the desired level of shine is achieved before moving on to a larger area.

Machine Buffing

Machine buffing is a method of polishing that utilizes a mechanical device to apply and distribute polish onto a surface. This method is often preferred because it can save time and effort, especially for larger surfaces like cars or floors. However, it is important to use caution when machine buffing as it can also cause damage to surfaces if not done correctly.

One important factor to consider when machine buffing is the type of pad being used. There are a variety of pads available, each designed for different purposes and surfaces. It is important to choose the appropriate pad for the job to avoid damaging the surface.

In addition to choosing the right pad, it is important to select the appropriate speed setting on the machine. A lower speed setting will provide a gentler polish, while a higher speed setting will increase the effectiveness of the polish. However, using too high of a speed on delicate surfaces can cause damage, so it is important to adjust the speed accordingly.

When applying polish with a machine buffer, it is important to evenly distribute the polish and apply it in a back-and-forth or circular motion. Start with a small area and gradually work your way to larger areas, ensuring that the polish is being evenly distributed and not applied too thickly in any one spot.

Table:

| Machine Buffing Do’s | Machine Buffing Don’ts |

|---|---|

| Choose the appropriate pad for the surface | Use too high of a speed on delicate surfaces |

| Adjust the speed setting accordingly | Apply polish too thickly in any one spot |

| Evenly distribute the polish in a back-and-forth or circular motion | Use a dirty or damaged pad |

| Start with a small area and gradually work your way to larger areas | Polish for too long in any one spot |

By following these machine buffing tips and using the appropriate tools and techniques, you can achieve a high-quality, polished surface without causing damage.

Preparation Tips

Preparing your surface before applying polish is an essential step in achieving a flawless shine. Neglecting this step can result in uneven or hazy finishes.

The following table outlines some preparation tips to ensure optimal results:

| Preparation Tip | Description |

|---|---|

| Wash and Dry | Before polishing, clean the surface of any dirt, debris, or dust. Rinse with water, and dry thoroughly with a soft cloth or microfiber towel. |

| Remove Old Polish | If you are polishing an object that has already been polished before, it is important to remove the old polish first. Old polish can build up and create a hazy finish. Use a polish remover or denatured alcohol to remove any old polish residue. |

| Protect Surrounding Areas | When polishing, take the necessary precautions to avoid getting polish on surrounding areas. Cover edges or crevices with tape or newspaper, and avoid getting polish on plastic or rubber surfaces. |

| Use the Right Tools | Make sure that you are using the right tools for the job. Use a soft cloth or microfiber towel for manual polishing, or a buffing pad for machine polishing. Avoid using abrasive materials that can scratch the surface. |

| Work in a Well-Ventilated Area | Polish can release fumes, so it is important to work in a well-ventilated area. Open windows, doors, or use a fan to increase air flow in the workspace. |

By following these preparation tips, you can ensure that your surface is ready for polishing, and that you achieve the best possible results.

Maintaining Your Shine

After spending the time and effort to polish your surfaces, the last thing you want is for that shine to fade away. It’s important to take steps to maintain your hard work so that you can continue to enjoy the beautiful finish for as long as possible. But how do you do that? In this section, we’ll explore some preventative measures you can take, cleaning tips to keep your surfaces looking their best, and some common mistakes to avoid that can undo all your hard work. Let’s dive in and learn about maintaining your shine.

Preventative Measures

Maintaining a polished surface requires effort and attention. To ensure that your surfaces stay shiny, there are several preventative measures to take.

Protection: Protecting surfaces from scratches and damages is the first step to preventing loss of shine. Use coasters for drinks, place mats under dining plates, and avoid dragging heavy items across surfaces.

UV Exposure: Excessive exposure to sunlight can damage surfaces and cause fading. Use window-coverings when necessary and avoid placing delicate items in direct sunlight.

Humidity: High humidity can cause oxidation on metal surfaces and wood to swell. Use dehumidifiers to control humidity and avoid placing metal objects in damp areas.

Cleaning: Regular cleaning is essential in maintaining any surface. Use cleaning products tailored to the surface type and avoid using abrasive cleaners or sponges as they can scratch surfaces.

Waxing: Applying wax to surfaces can protect them from damage, increase shine and make cleaning easier. Choose a wax suitable for the surface and follow the instructions carefully.

By following these preventative measures, you can help maintain the shine on your surfaces and prevent unnecessary damage.

Cleaning Tips

To maintain the shine on your polished surfaces, it is important to clean them regularly. Here are a few tips to keep in mind:

- Use the right cleaning products: Be sure to use a cleaning product that is safe for the surface you are cleaning. Avoid using harsh chemicals that can damage or dull the surface. Read the label carefully and follow the manufacturer’s instructions.

- Use a soft cloth: When wiping down your surfaces, use a soft cloth such as a microfiber towel or chamois. Avoid using abrasive materials like steel wool or scrubbing pads, as they can scratch the surface and ruin the shine.

- Wipe in the direction of the grain: When wiping down surfaces with a grain or pattern, always wipe in the direction of the grain. This helps to avoid leaving streaks and maintains the polished finish.

- Dry thoroughly: After cleaning, be sure to dry the surface thoroughly with a clean, dry cloth. This helps to prevent water spots and streaks from forming.

- Avoid harsh cleaning tools: Do not use any tools that could scratch the surface of the polished material, such as abrasive cleaners or rough sponges. Instead, use a soft-bristled brush or a soft cloth to gently remove dirt and stains.

- Regular cleaning: To keep your surfaces looking their best, it’s important to clean them regularly. Fingerprints and smudges can quickly build up on polished materials, so it’s best to wipe them down every few days.

Keep these cleaning tips in mind to ensure that your polished surfaces stay looking shiny and new.

Common Mistakes to Avoid

It’s important to know what to avoid in order to maintain the shine on your surfaces. Here are some common mistakes that you should steer clear of:

- Using the wrong type of polish: Make sure that you choose a polish that is suited to your specific surface type and chemical composition.

- Skipping the preparation step: Skipping the preparation step can lead to poor results. Make sure that you thoroughly clean your surface and remove any previous polish residue before polishing.

- Applying too much polish: Over-applying polish can lead to streaks and a dull finish. It’s important to only use the recommended amount for your specific surface.

- Using a dirty polishing cloth: Using a dirty cloth can transfer dirt and debris onto your newly polished surface. Make sure to use a clean microfiber cloth for each polishing session.

- Not allowing the polish to dry: Make sure to allow the polish to fully dry and cure before buffing. Otherwise, you may remove the polish and be left with a patchy finish.

- Using a harsh chemical cleaner before polishing: Using a harsh chemical cleaner before polishing can damage your surfaces and negate the effects of the polish. Stick to a mild cleaner or soap and water before polishing.

- Using a circular motion while buffing: Using a circular motion while buffing can lead to swirl marks on your surfaces. Instead, use straight back and forth motions.

By avoiding these common mistakes and following the proper techniques, you can maintain a beautiful shine on your surfaces.

Conclusion

In conclusion, the science behind polish and shine is a fascinating subject. Understanding the chemical properties of polish and the way it interacts with surfaces can help you achieve the perfect shine. Using the right polish and techniques for your specific surface type and chemical composition is crucial for optimal results.

Maintaining your shine requires some preventative measures and attention to cleaning techniques to avoid common mistakes. By implementing the tips and tricks outlined in this article, you can keep your surfaces looking shiny and new for longer periods of time.

Remember that a smooth surface is essential for achieving a high shine, and the right polish can help you achieve it. Additionally, the way light interacts with surfaces plays a key role in the final outcome of your polishing efforts.

Ultimately, by understanding the science behind polish and shine, you can take your polishing efforts to the next level and achieve the desired results. With patience and attention to detail, you can enjoy surfaces that are not only clean and well-maintained but also dazzlingly shiny.

Frequently Asked Questions

What is the difference between polishing and waxing?

Polishing is the process of removing imperfections and restoring shine to a surface, while waxing adds a layer of protection to the surface.

Will polishing damage my car’s paint?

No, as long as you use the correct technique and products, polishing will not damage your car’s paint.

How often should I polish my car?

It depends on how often you drive your car and the condition of the surface. Typically, once or twice a year is sufficient for most vehicles.

Can I use the same polish on all surfaces?

No, different surfaces require different types of polish. Be sure to read the label and use a polish that is designed for the specific surface you are working on.

Do all polishes contain abrasives?

No, some polishes are abrasive and some are non-abrasive. It is important to choose the right type of polish for your specific needs.

Do I need a machine to polish my car?

No, you can polish your car by hand. However, using a machine can make the process quicker and more efficient.

Can I use water to clean my car before polishing?

Yes, using water to wash your car before polishing is recommended. However, be sure to dry the surface thoroughly before applying polish.

How long does it take to polish a car?

It depends on the size of the vehicle and the condition of the surface. Typically, it can take anywhere from a few hours to a full day to polish a car.

Is it necessary to wear gloves when polishing?

It is recommended to wear gloves when polishing to protect your hands from chemicals and to help prevent skin irritation.

Can I use a spray wax instead of polish?

No, spray wax is not a substitute for actual polishing. Spray wax is designed to provide a quick and temporary shine, while polish restores and enhances the surface.